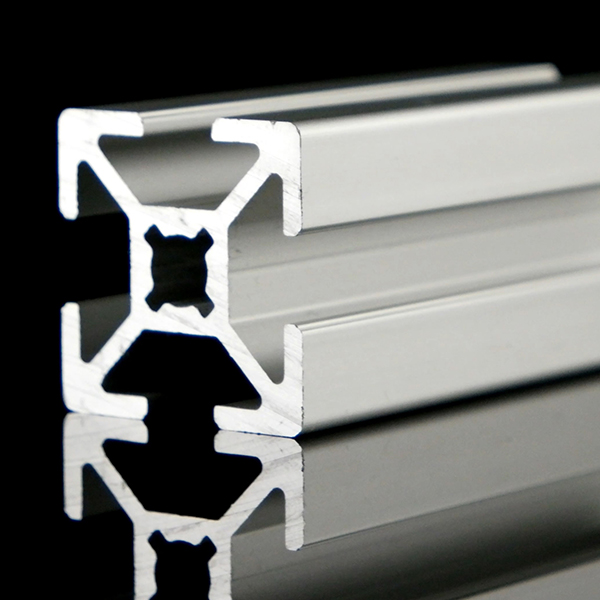

Metal extrusion is a manufacturing process used to create complex cross-sectional shapes by forcing a metal billet or a heated metal through a die or a series of dies. The material used in metal extrusion can vary depending on the application, but common metals include Aluminium, Copper, Steel, and Titanium.

The size limitations of metal extrusion depend on various factors such as the material being extruded, the complexity of the shape, and the capabilities of the extrusion equipment.

PRECiSMART offers extensive and adaptable manufacturing capacity and capabilities.

We will collaborate with you to ensure you obtain the essential components with precision and efficiency,

meeting your specific requirements effectively.