3D printing, also known as additive manufacturing, is a technology that creates three- dimensional by layering materials according to a digital design. It involves the process of gradually depositing successive layers of material until the entire object is created.

When it comes to size, 3D printing can produce objects ranging from small, intricate designs to large, architectural models or even full-scale buildings. However, the maximum size of an object that can be 3D printed depends on the specific printer and its capabilities. However, parts up to size range 200mm X 200mm X 200mm can be easily handled with intricated shapes.

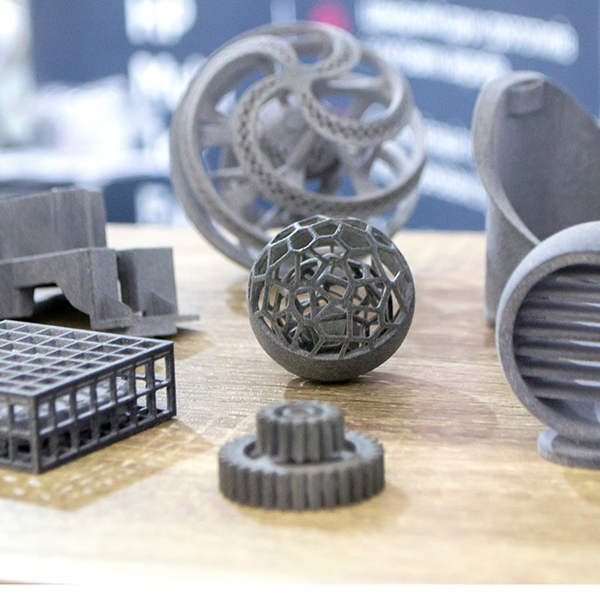

Shape possibilities in 3D printing are extensive. Unlike traditional manufacturing methods, which are often limited by Molds or other constraints, 3D printing allows for complex and customized shapes. It can create objects with intricate details, overhangs, hollow structures, and even internal moving parts.

The material possibilities in 3D printing are vast and constantly expanding. Different 3D printers support various materials, including plastics (such as ABS or PLA), metals (like aluminium, titanium, or steel), ceramics, glass, resins, and even food-based materials. The choice of material depends on the printer technology and the intended use of the printed object.

Overall, 3D printing offers a wide range of size, shape, and material possibilities, making it a versatile and innovative technology for creating unique and customized objects.

PRECiSMART offers extensive and adaptable manufacturing capacity and capabilities.

We will collaborate with you to ensure you obtain the essential components with precision and efficiency,

meeting your specific requirements effectively.